| 产品名称 : | CTH型气动火炮擦膛机CTH-type Pneumatic Gun Barrel Cleaner |

| 品牌: | 龙之盾 |

| 型号: | CTH-1 |

CTH型气动火炮擦膛机CTH-type Pneumatic Gun Barrel Cleaner

◆模块化设计,操作简单,使用可靠;

Modular design, simple operation and reliable use;

◆外部气源可采用压缩空气、车辆轮胎充气系统,或室内空气供应站等多种方式获得,节省人力;

External air source can be obtained by means of compressed air, vehicle tire inflation system, or indoor air supply station, savingmanpower;

◆气动马达直接将雾化的擦膛液喷洒在身管内膛表面,实现高效擦膛;

The pneumatic motor sprays the atomized barrel detergent directly on the inner surface of gun barrel, realizingefficientbarrel cleaning;

◆全套设备结构体积小,重量轻,可单兵携带和操作;

The full set of equipment features small structure size and lightweight, and can becarried and operated by a single soldier;

◆炮刷为系列化产品,规格多、刷头可更换;

As a series of products, the barrel brush features various specifications and replaceable brush head;

◆每种规格炮刷种类齐全,还可根据用户需

求进行个性化定制;

Each specification of barrel brush features wide selection and can also be customized according to the users demand;

◆身管清理系统适用范围广,对于陆军25~300mm口径火炮实现身管的清洁、保养。

The gun barrel cleaning system applies to a wide range, and realizes cleaning and maintenance of army gun barrel of caliber between 25~300 mm.

适用于火炮,装甲车

Applies to artillery, armored car

适用于野战,保修站

Applies to field operations, repair service station

火炮射击后,炮管处于高温高压环境中,火药发射燃烧生成物会粘附在身管内膛表面,形成瓦斯烟等污物残留;同时弹带挤入膛线也会形成挂铜。上述残留物如不及时物清除,将影响弹丸的正常运动,加速炮膛的烧蚀和磨损,影响射击精度,降低身管寿命,因此,火炮内膛的清洁保养极为重要。

After artillery fires, the barrel is under high temperature and high pressure environment, combustion products of gunpowder firingwill adhere to the inner surface of the barrel, forming gas smoke and other dirt residue;meanwhile the engraving process of driving band into rifle will also form copper coat. If the above residues are not removed in time, it will affect the normal movement of the projectiles, accelerate the ablation and abrasion of the gun barrel, affect the shooting accuracy, and reduce the life of gun barrel, therefore, the cleaning and maintenance of the inside of gun barrel is extremely important.

气动火炮擦膛机就是为解决火炮射击后快速、高效清除身管内膛残留物而设计的,同时能够完成火炮的启封和封存。

Pneumatic gun barrel cleaneris designed to solve the problem of quickly and efficiently removal of the residue from the inside of gun barrel after the artillery fire, and can complete the opening and sealing of artillery at the same time.

气动火炮擦膛机适于配备于陆军部队各类分队,用于陆军装备25mm至300mm火炮身管擦拭保养。在火炮启封、发射炮弹后和封存各个阶段,对火炮身管内壁进行清理和涂油,完成火炮身管擦拭保养工作,擦膛液能够自动雾化,有效提高火炮保养效能。整套设备结构紧凑、操作简单、使用可靠,单兵携行能够完成火炮保养工作。

Pneumatic gun barrel cleaners are suitable for all types of units of the army force and are used for cleaning and maintenance of gun barrel of 25mm~300mm configured for army. In each phase of artillery seal opening, firing and sealing, clean the inner wall of gun barrel and apply oil, complete the gun barrel wiping maintenance work, the barrel cleaning detergent can be automatically atomized, so as to effectively improve the effectiveness of artillery maintenance. The complete set of equipment is compact, simple to operate, and reliable to use, and can be carried by single soldier to complete artillery maintenance work.

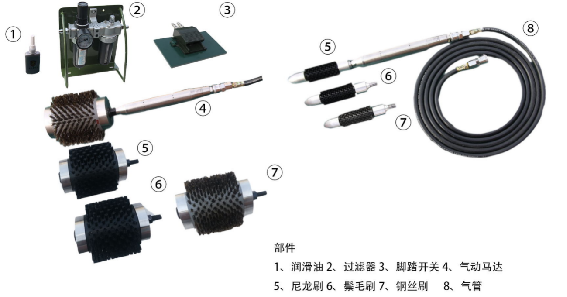

气动火炮擦膛机由气动马达1套、炮刷1套(包括刮油刷、除铜刷和涂油刷各1个,具体规格根据部队需要组套)和附件1套(含气管、过滤器、脚踏开关、接头等)组成。

Pneumatic gun barrel cleaner consists of 1 set of pneumatic motor, 1 setof barrel brush (including 1 oil scraping brush, 1 copper removing brush and 1 oil brush respectively, the specific specifications should be configured according to demand of the army) and 1 set of accessories (including air tube,filter,foot switch andconnector, etc.).

Parts:

1. Lubricant 2. Filter 3. Foot switch 4. Pneumatic motor 5. Nylon brush 6. Brush with bristle attachment to brush body 7. Steel wire brush 8. Air tube

气动火炮擦膛机采用模块化设计,操作简单,使用可靠;气源经过滤、减压后驱动马达伸缩,带动炮刷在身管内膛沿膛线方向运动;雾化的擦膛液通过马达直接喷洒在身管内膛表面,实现高效擦膛。

Pneumatic gun barrel cleaner adoptsmodular design, simple operationandreliable use; gas sourcepropels motor to telescope to drive brush to move along rifle direction in the inside of gun barrel; the atomized barrel detergent is sprayed directly through the motor on the inner surface of gun barrel to achieveefficientgun barrel cleaning.

全套设备可装入携行箱和携行袋中,其中气动马达和附件装入携行箱,炮刷放入携行袋,全部重量为25Kg ,可单兵携带和操作。

A full set of equipment can be loaded into the carrying case and carrying bag, in which pneumatic motor and accessories are loaded into the carrying case, the barrel brushis placed into the carrying bag, the total weight is 25Kg, and the full set of equipment can be carried and operated by a single soldier.

炮刷为系列化产品,其规格在直径φ25mm~φ300mm范围内,共计九种,刷头可更换;每种炮刷标准配置包括刮油刷、除铜刷和涂油刷三件,也可根据用户需求进行个性化定制。

Barrel brush is a series of products, itsspecification is in the range of diameter φ25mm~300mm, totaling nine types, and brush head can be replaced; standard configuration of each brush includes 3 pieces ofoil scraping brush, copper removal brush and oil brush, and can alsobecustomizedaccording to user demand.

气动火炮擦膛机已经在部队应用,其中气动马达已获专利授权。外部气源可采用压缩空气、车辆轮胎充气系统,或室内空气供应站等多种方式获得。尺寸小,重量轻,操作者易于掌控。

Pneumatic gun barrel cleaner has been used in the army, in which pneumatic motors have been granted with patent. Externalair sourcescan be obtained by multiple means of compressed air, vehicle tire inflation system, or indoor air supply station.And the product features small size, lightweight and easiness of control by the operator.

气动火炮擦膛机与龙之盾公司生产的新型环保快洁擦膛剂同时使用,可获得最好的保养效果。

Pneumatic gun barrel cleaner anda new environmental protection fast-cleaning barrel detergent produced by Loongshield can be used at the same time to obtain the best maintenance effect.

气动火炮擦膛机

Pneumatic Gun Barrel Cleaner

技术规格

Technical Specifications

1.1 性能参数

Performance parameters

1) 工作压力:0.6~0.8MPa

Working pressure:0.6~0.8MPa

2) 空气流量:≤0.8m³/min

Air flow rate:≤0.8m³/min

3) 气动马达:≥10m/min

Pneumatic motor:≥10m/min

4) 工作效率:能有效清除火炮发射后身管内的残留物,完成火炮身管启封和封存,平均维护保养一次≤30min;

Work efficiency: The product can effectively remove the residue inside the gun barrel after the artillery fire, complete the gun barrelseal opening and sealing for storage, and the average maintenance takes ≤30min;

5) 炮刷适用口径:

Brushes are available in the following caliber:

25/30/35/37/57/76/82/100/105/120/122/125/130/152/155/300mm

6) 炮刷种类:刮油刷、除铜刷、涂油刷三种;

Barrel brush types: 3 types of oil scraping brush, copper removal brush, oil application brush;

7) 外形尺寸:携行箱≤650×450×200 mm

External dimension: Carrying case ≤ 650×450 × 200 mm

携行袋≤500×200×300 mm(25~155规格炮刷)Carrying bag ≤ 500 × 200 × 300 mm (25~155 brush)

8) 携行袋≤350×350×300 mm(300规格炮刷)

Carrying bag ≤ 350×350×300 mm (300 brush)

9) 质 量:≤25kg

Mass:≤25kg

10) 适用炮管:适用各种类型炮管(如防卫炮,舰炮,火炮等)

Applicable for gun barrel: applicable forvariousgun barrels (e.g. defense guns, warship guns and artillery, etc.)

1.2 通用质量特性参数

General quality characteristic parameters

1) 可靠性:平均故障间隔时间(MTBF)≥500h;

Reliability: mean time between failures (MTBF) ≥ 500h;

2) 维修性:维修方便,易操作。

Repairability: easy to repair and easy to operate.

3) 保障性:

Indemnificatory:

Ø 随设备带有使用维护说明书,包括使用、维修方面的详细说明:

Use/maintenance instruction manual is attached to equipment, including detailed description for aspects of use and repair:

Ø 随设备带有光盘,用于演示各种操作;

CD is attached to equipment for demonstration of various operations;

Ø 随设备带有备用管夹,便于可靠地固定气管。

Spare tube clip is attached to equipmentfor reliable fixation of air pipe.

4) 测试性:有工作压力显示装置。

Testability: working pressure display device is available.

5) 安全性:对涉及人员安全的作业环境、操作部位采用标牌进行警示。

Safety: sign board is adopted for warning regarding working environment and operating positions involving personnel safety.

6) 环境适应性:

Environmental adaptability:

Ø 工作温度:-40℃~+50℃;

Operating temperature:-40℃~+50℃;

Ø 储存温度:-43℃~+70℃;

Storage temperature:-43℃~+70℃;

Ø 高原适应性:适用于4500m以上高海拔地区;

Highland adaptability: suitable for high altitude regions above 4500m;

Ø 耐湿热性:满足GJB150.9A—2009《军用装备实验室环境试验方法 第九部分:湿热试验》相关要求;

Damp-heat resistance: meet the related requirements of GJB150.9A-2009 Laboratory Environmental Test Method for Military Equipment - Part 9: Damp Heat Test;

Ø 耐盐雾性:满足GJB150.11A—2009《军用装备实验室环境试验方法 第十一部分:盐雾试验》相关要求;

Salt spray resistance: meet therelated requirements of GJB150.11A-2009 Laboratory Environmental Test Method for Military Equipment - Part 11: Salt Spray Test;

Ø 抗 振 性:满足GJB150.16A—2009《军用装备实验室环境试验方法 第十六部分:振动试验》相关要求或按技术协议要求的其他条款;

Vibration resistance: meet the related requirements of GJB150.16A-2009 Laboratory Environmental Test Method for Military Equipment-Part 16: Vibration Test or other provisions as required by the technical agreement;

Ø 耐冲击性:满足GJB150.18A—2009《军用装备实验室环境试验方法 第十八部分:冲击试验》有关要求;

Impact resistance: meet the related requirements of GJB150.18A-2009 Laboratory Environmental Test Method for Military Equipment – Part 18: Shock Test;

Ø 淋雨要求:满足GJB150.8A—2009《军用装备实验室环境试验方法 第八部分:淋雨试验》相关要求。

Rain requirements: meet the related requirements of GJB150.8A-2009 Laboratory Environmental Test Method for Military Equipment-Part 8: Rain Test.

气动火炮擦膛机CTH-Ⅰ、CTH-Ⅱ、CTH-Ⅲ型

CTH-Ⅰ,CTH-Ⅱand CTH-ⅢPneumatic Gun Barrel Cleaners

|

型号 Model |

规格 Specifications |

适用口径 Applicable caliber |

|

CTH-Ⅰ |

Φ23×228mm |

25mm |

|

Φ27×228mm |

30/35mm |

|

|

Φ32×228mm |

37/57/76/82mm |

|

|

CTH-Ⅱ |

Φ38×270mm |

100/105/120/122/125/130/152/155mm |

|

CTH-Ⅲ |

Φ38×270mm |

300mm |

装箱清单

Packing List

|

序号Serial number |

名称 Name |

数量Quantity |

单位Unit |

备注 Remark |

|

1 |

气动马达 Pneumatic motor |

1 |

台 Set |

|

|

2 |

气管 Airtube |

3 |

条Piece |

|

|

3 |

过滤器油雾器二联件Filter/atomizer 2-in-1 |

1 |

件Piece |

|

|

4 |

脚踏开关 Foot switch |

1 |

件Piece |

|

|

5 |

润滑油Lubricant |

1 |

瓶Bottle |

100ml |

|

6 |

工具袋 Tools bag |

1 |

套 Set |

活口扳手1件 1 adjustable spanner 固定口厚扳手1件 1 non-adjustable thick spanner 固定口薄扳手1件 1 non-adjustable thin spanner 内六角扳手1件 1 inner hexagon spanner 生料带1卷1 roll of PTFE tape |

|

7 |

随机资料 Documents attached to equipment |

1 |

套 Set |

说明书、保修卡、合格证、装箱清单 Instruction manual, warranty card, certificate of quality and packing list |

|

8 |

箱子及内饰 Box and interior trim |

1 |

套 Set |

|

|

9 |

炮刷 Barrel brush |

|

|

个性化定制 Customization |

好评度